Rear Brake Kits

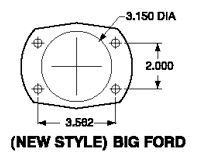

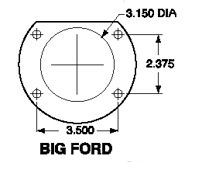

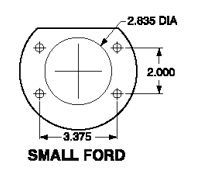

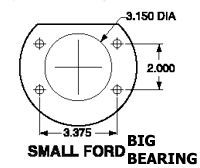

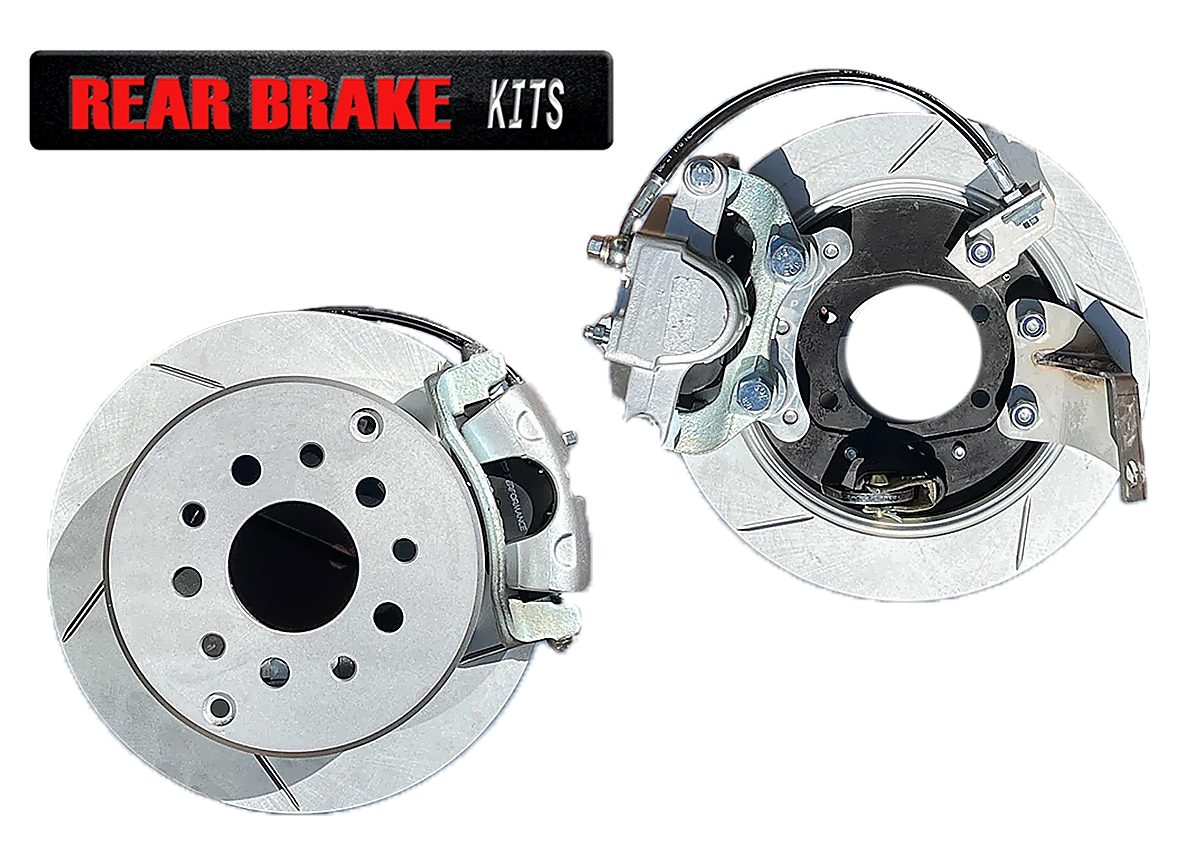

The versatile modular design of the RRS disc brake rear conversion will work with all Ford 9" differentials and wheel sizes 14" to 20". Different braking plate rotor sizes means if you have a Ford 9", you can easily upgrade your rear brakes. The axle bearing-to-axle flange relationship is vital for correct calliper-to-disc alignment. Multiple spacers are supplied by RRS to correct alignment. RRS supply custom backing plate to line up with your diff flange bolt pattern.

The RRS Drum In Disc system means you get the best of both worlds, beautifully made, vented rotor disc brakes, and drum brakes that allow no fuss hook up to your existing hand brake assembly.

RRS rear brake kit including hand brake system from AUD$2070 including GST

Rear Drum in Disc Braking Systems

RRS offers a comprehensive range of rear brake options to suit all driving needs and budgets.

Match your wheel size and front brake size, then identify your axle flange end. Without changing your handbrake cable, you can upgrade your rear drum brake to disc, match your front brake stopping and improve the performance, safety and reliability of your classic.

The RRS Advantage

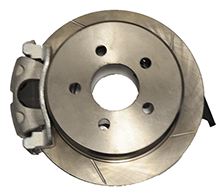

The RD1 kit is designed to works with 14",15" original rims.

The RD1 balances perfectly with the RRS phase1 front brake system to have you stopping 40% better than stock.

RD1 kit specifications

- 11-inch/285ml RRS rotors

- Single piston silver calliper including all attaching hardware

- Banksia style park brake

TO SUIT 14"OR 15" WHEELS

The RRS Advantage

The kits are designed to bolt on without any modifications to STANDARD Ford 9" axle housings. If the axle housing has been modified, such as: narrowed, fitted to a non factory application or has after market axles fitted.

RD2 kit specifications

- 12.4-inch/315mm RRS rotors

- Single piston red calliper including all attaching hardware

- Banksia style park brake

TO SUIT 16"TO 20" WHEELS

TO SUIT 17"TO 20" WHEELS

The RRS Advantage

- Precision laser cut and C.N.C. machined parts

- Laser cut brackets

- Use your factory original park brake cables

- Compatible with Ford 9" rear axle

RD4 kit specifications

- 13.7-inch/330mm RRS rotors

- 6 piston mini VTTR red calliper including all attaching hardware

- Banksia style park brake

TO SUIT 16"TO 20" WHEELS

How to Disassemble Ford 9” Axles: Brake Drum & Axle Shafts

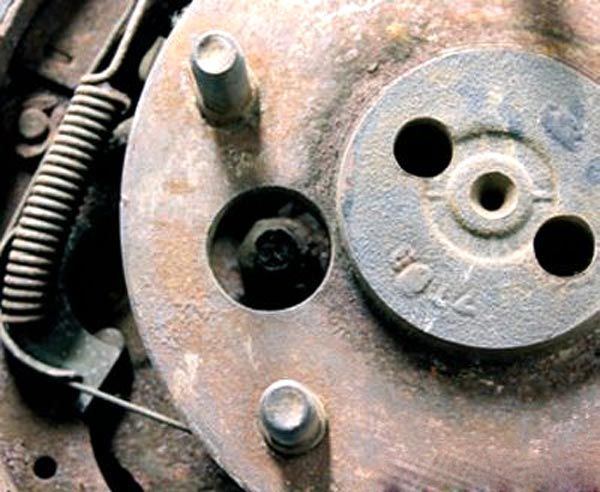

The first step is to have the vehicle on jack stands and the wheels and tires removed. After you remove the brake drums be sure to set them aside in a clean and safe place. Remember to label the axle shafts according to the side in which they were installed, as they are different lengths. There is an access hole in the wheel flange that allows you to get a socket on the nut that holds the axle shaft and brake backing plate in place. The rest, as they say, is a piece of cake.

Applications

Rear Brake Kits

How To Get A Quote

We can provide door to door freight. Fill out below to get a quote.

Ready to Take Your Classic to the Next Level?

If you have any questions, concerns, or need any parts advice for your classic ride, please don’t hesitate to reach out to the RRS team. We’re always happy to assist!